One pot for everything

Smart cooking // The all-in-one solution really does exist – at least when it comes to cooking pots. Wired Cooking has developed a pot that can prepare (almost) any dish perfectly. But that’s not all: it also brews beer and ferments vegetables. And the best part is that you don’t even need a stove with the Wired Cooker. The revolutionary cooker is controlled via an app.

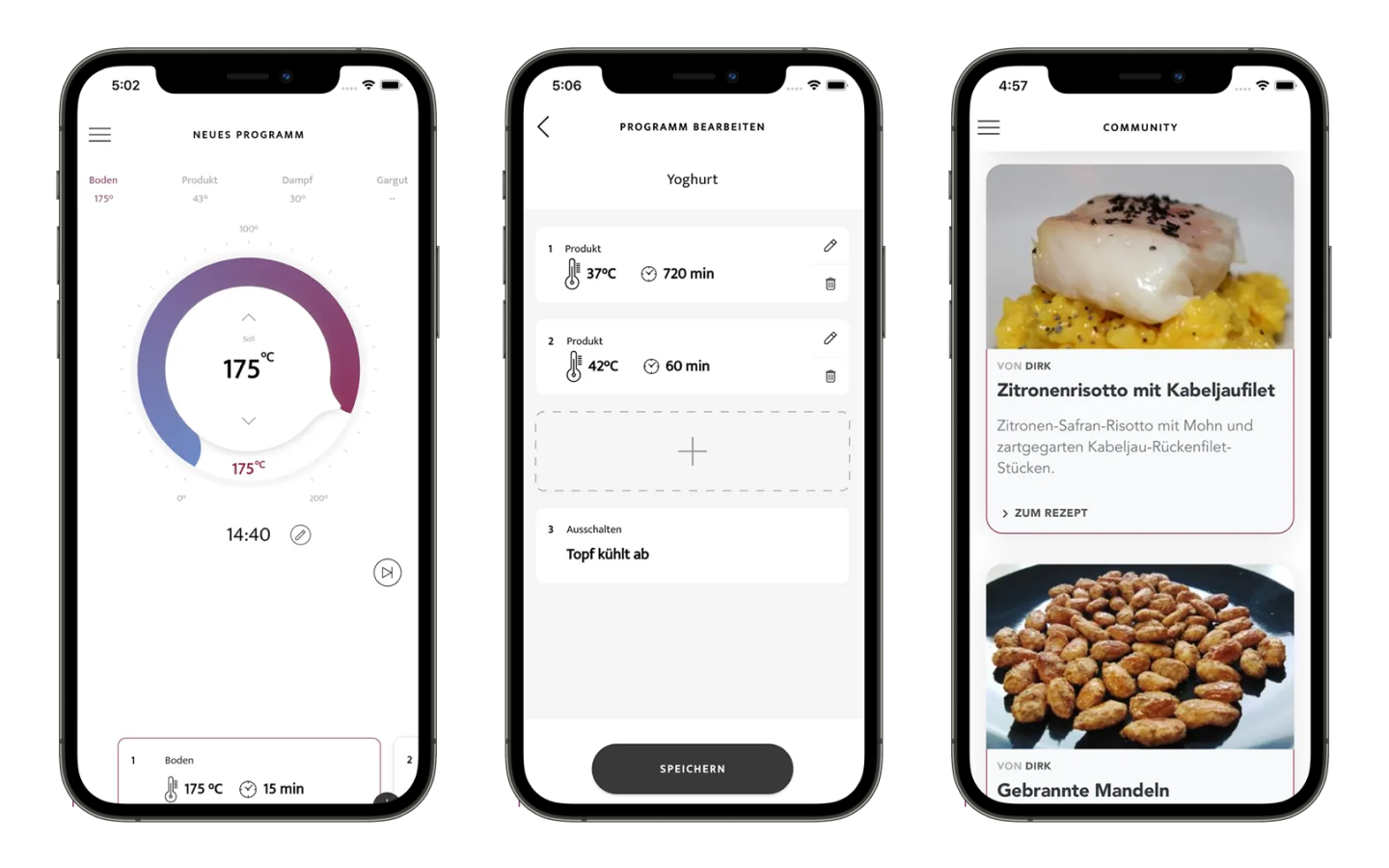

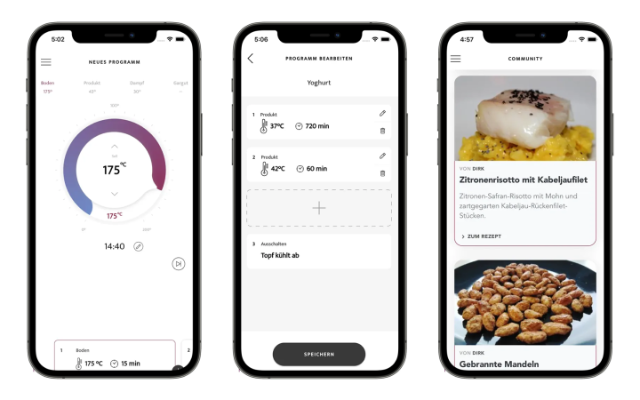

Every innovation starts with an idea and the question of what the future might look like. Dirk Uhlenhaut and Jochen Ganz are two ambitious amateur cooks. They had a clear vision: they wanted a tool that didn’t just perform one special function, like a rice cooker, fryer, or fondue pot. They wanted an all-in-one tool that completes entire cooking processes. In other words, a rice cooker that boils rice to the perfect texture for sushi, for example, and then browns it for fried rice as well. After all, special dishes require special gadgets. Before long, you have a whole collection including a fryer, a steamer, a fondue pot, and a rice cooker. And it goes without saying that you don’t use these appliances very often. Dirk Uhlenhaut and Jochen Ganz’s response to this problem is a multitasker: the Wired Cooker. The Wired Cooker isn’t just a gadget for ambitious amateur chefs, though. It opens up a world of possibilities that go beyond everyday cooking. It ferments vegetables, serves as a fermentation tank for beer, pasteurizes raw milk, and sterilizes baby bottles. Users control the cooker via a mobile app developed by ti&m. They can download cooking programs for a wide range of recipes from the Wired Cooking website. But they can also program them individually and create dishes themselves. The app lets them control the cooking temperature in the Wired Cooker perfectly – they can set the temperature for a bain-marie to the exact degree. After all, certain cooking processes – such as caramelizing sugar or melting chocolate – require almost exactly the right temperature for an optimal result. Caramel becomes bitter if you don’t remove it from the heat at the right moment. Chocolate on the other hand turns gray when overheated.

The perfect method for a complex sequence of cooking steps

The app is easy to program and control. This allows users to cook complex dishes involving sequences of multiple steps. For example, a user might program the cooker to fry vegetables on a high heat for five minutes. Then the program adds the stock and reduces the mixture for three minutes. After this, it simmers at 175 degrees for 15 minutes. The app shows the cook when to add each ingredient. And it automatically sets the cooker to the right temperature. This means the food cannot burn or be overcooked. Users therefore don’t need to watch the clock and the temperature constantly. This reduces monitoring to a minimum. The Wired Cooker lets the cook set any time and temperature. Users can easily combine these two parameters step by step.

Q&A

ti&m developed the mobile app that controls the Wired Cooker. This project was unfamiliar territory for Lisa Kondratieva, Head of Mobile & IoT at ti&m.

What was new about this project for you and your team?

We devised the concept for the app in design sprints. Then we developed and implemented it. So there was nothing unusual about the project up to that point. On the IoT team, we are used to connecting hardware and software. The big difference was the high level of dependence on the hardware. By that I mean the fabrication of the controller. Developing an app alongside a controller that was still being manufactured was really challenging.

What aspects did you focus on while developing the app?

User-friendliness. For me, that goes beyond simple, logical guidance for users. It’s also about the functionality of using a cooking pot. After all, the pot had to work in a cabin in the Swiss mountains or in a campsite in Scandinavia. So being able to control the pot offline with the app via Bluetooth was a requirement. We implemented the cross-platform app using the agile methodology with Flutter. That made sure the app would run on both iOS and Android.